TO SYSTEMS

The TO filter systems utilize standard carbon block technology that removes sediment and chlorine from the water supply improving the taste of the drinking water, soda, and juice beverages.

Flow Rate:

1.65

gpm.

Capacity: 10,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 3.3

gpm.

Capacity: 20,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.95 gpm.

Capacity: 30,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate:

6.6 gpm.

Capacity: 40,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: 15,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.0

gpm.

Capacity: 30,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 6.0

gpm.

Capacity: 45,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 8.0

gpm.

Capacity: 60,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

TOS SYSTEMS

The TOS filter systems provide chlorine removal with scale control utilizing standard carbon block technology that removes sediment and chlorine from the water supply improving the taste of the water and reducing possible chlorine related corrosion issues.

Flow Rate:

1.65

gpm.

Capacity: 10,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 3.3

gpm.

Capacity: 20,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 4.95 gpm.

Capacity: 30,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 6.6 gpm.

Capacity: 40,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 2.0

gpm.

Capacity: 15,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 30,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 45,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 8.0 gpm.

Capacity: 60,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

TOF SYSTEMS

The TOF filter systems utilizes a special filter that removes both sediment and chlorine but has a higher sediment loading capacity and reduced chlorine removal capacity. This is a premium product that is mostly used where the standard TO filter plugs prematurely from excess sediment in the water supply or where lower pressure drop is important for equipment operation.

Flow Rate: 1.5 gpm.

Capacity: 7,500 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 3.0 gpm.

Capacity: 15,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.5 gpm.

Capacity: 22,500 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 30,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: 12,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 24,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 36,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 8.0 gpm.

Capacity: 48,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

TOSF SYSTEMS

The TOSF filter systems utilizes a special filter that removes both sediment and chlorine with scale control but has a higher sediment loading capacity and reduced chlorine removal capacity. This is a premium product that is mostly used where the standard TOS filter plugs prematurely from excess sediment in the water supply or where lower pressure drop is important for equipment operation.

Flow Rate: 1.5 gpm.

Capacity: 7,500 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 3.0 gpm.

Capacity: 15,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 4,5 gpm.

Capacity: 22,500 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 30,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: 12,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 24,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 36,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate: 8.0 gpm.

Capacity: 48,000 gal. (Chlorine Removal)

Applications: Ice Machines, Coffee/Tea, Proofers, Deck/Rack Ovens

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

TOC SYSTEMS

The TOC filter systems utilize a catalytic carbon block technology that removes sediment, chlorine and chloramine from the water supply improving the taste of the drinking water, soda, and juice beverages.

Flow Rate: 1.65 gpm.

Capacity: 3,500 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 3.3 gpm.

Capacity: 7,000 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.95 gpm.

Capacity: 10,500 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 6.6 gpm.

Capacity: 14,000 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: 5,000 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 10,000 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 15,000 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 8.0 gpm.

Capacity: 20,000 gal. (Chloramine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

SD SYSTEMS

The

SD filter systems provide sediment filtration utilizing a premium high grade polypropylene 5 micron melt blown filter. This is specifically used as a pre-filtration system.

Flow Rate:

1.65 gpm.

Capacity: N/A

Applications: Pre-filtration

Download Spec Sheet:

Flow Rate: 3.3

gpm.

Capacity: N/A

Applications: Pre-filtration

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: N/A

Applications: Pre-filtration

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: N/A

Applications: Pre-filtration

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

SDS SYSTEMS

The SDS filter system provide sediment filtration & scale control utilizing a premium high grade polypropylene 5 micron melt blown filter. The sediment filter allows for chlorine to pass through the system helping control bacterial growth inside the ice machines where this is an issue.

Flow Rate:

1.65 gpm.

Capacity: N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 3.3 gpm.

Capacity: N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 4.95 gpm.

Capacity: N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 6.6 gpm.

Capacity: N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity:

N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate: 8.0 gpm.

Capacity:

N/A

Applications: Ice Machines

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

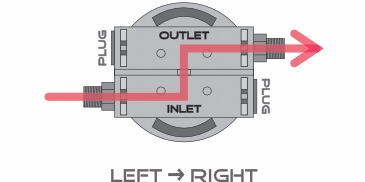

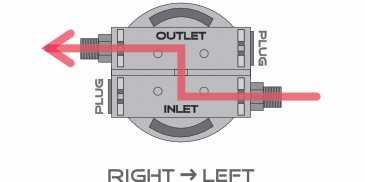

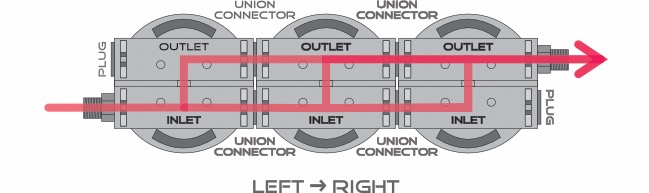

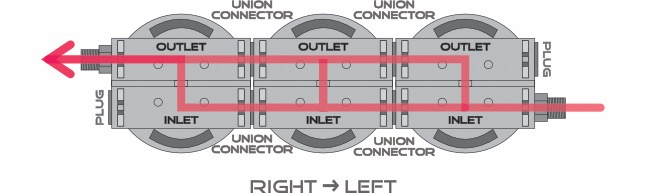

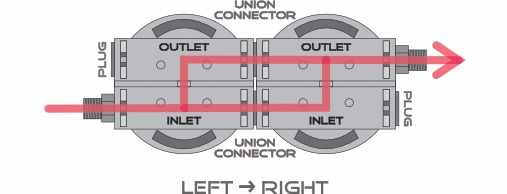

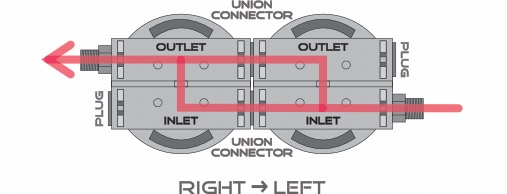

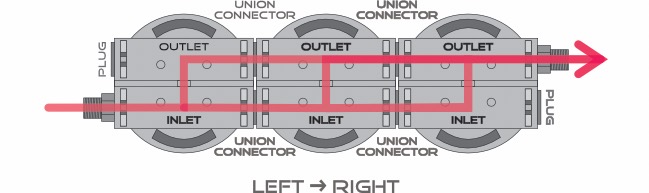

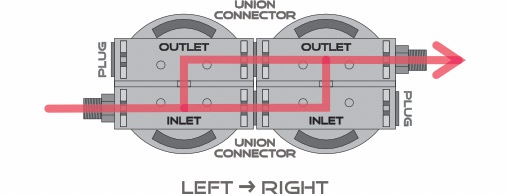

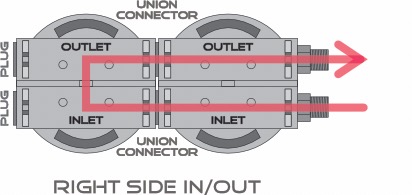

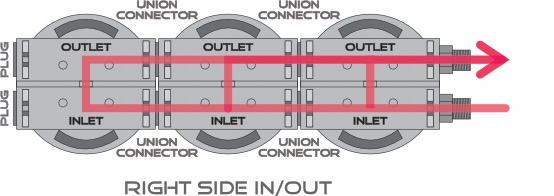

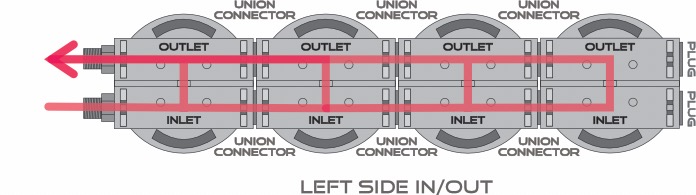

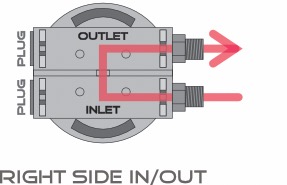

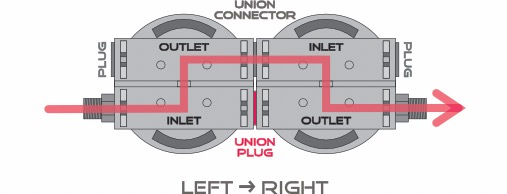

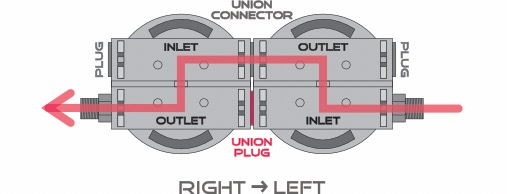

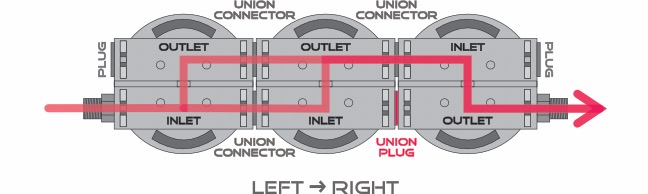

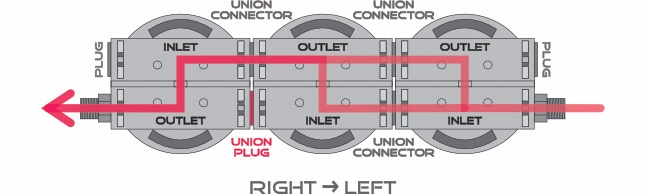

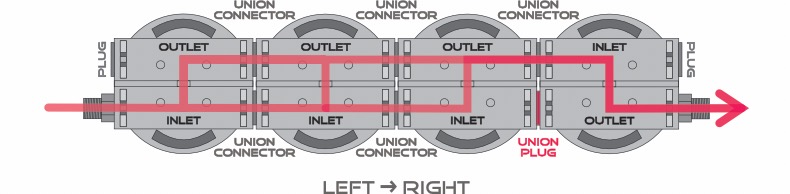

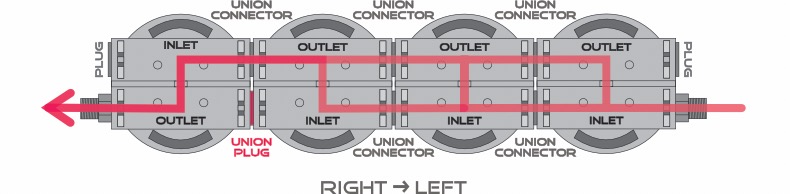

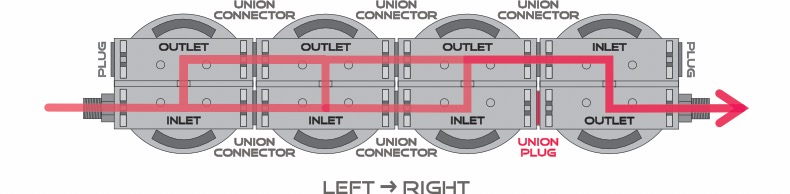

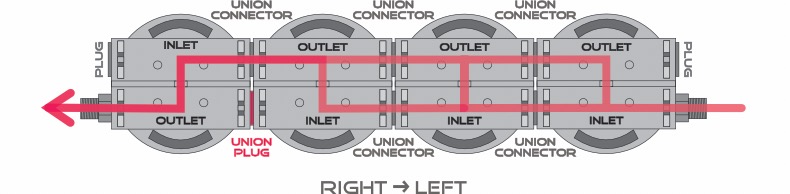

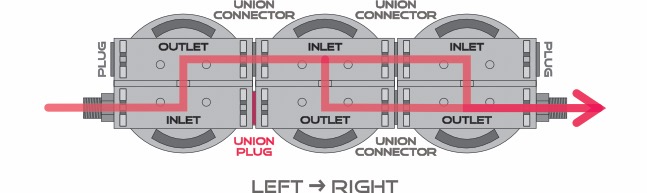

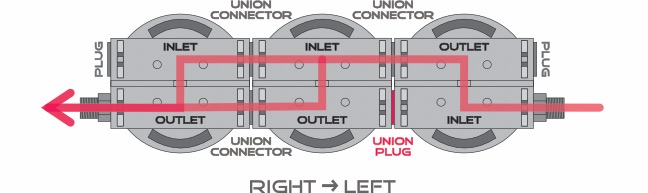

SERIES SYSTEMS

The

Series filter systems provide sediment filtration, chlorine removal and mineral scale control. This system has its heads manifolded together in a Series configuration that allows water to pass from one filter to the next. By request, Series systems are available with TOF and TOC filters.

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 1.65 gpm.

Capacity: 10,000 gal.

Applications: Steamers, Bakery Equipment

Download Spec Sheet:

Flow Rate: 3.3 gpm.

Capacity: 20,000 gal.

Applications: Steamers, Bakery Equipment

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: 15,000 gal.

Applications: Steamers, Bakery Equipment

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 30,000 gal.

Applications: Steamers, Bakery Equipment

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 30,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 45,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

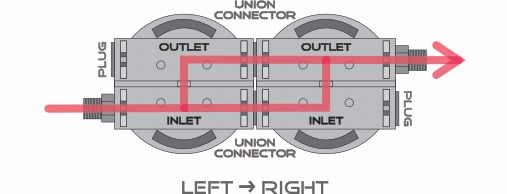

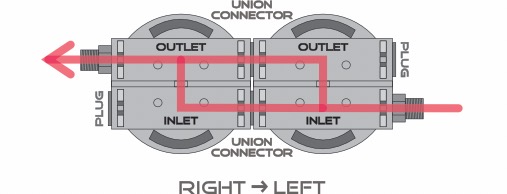

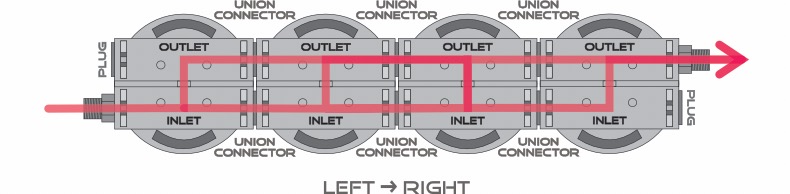

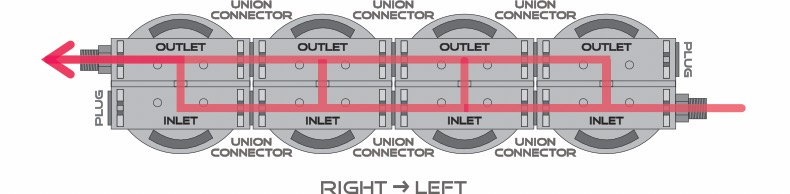

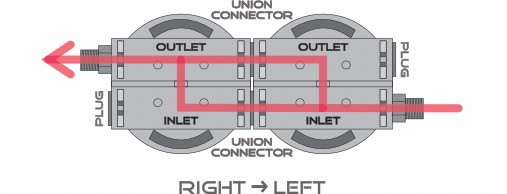

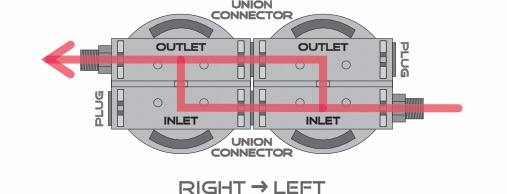

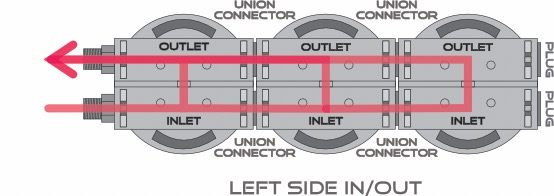

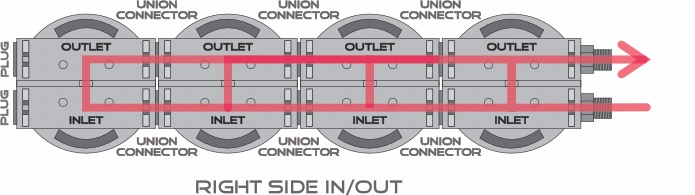

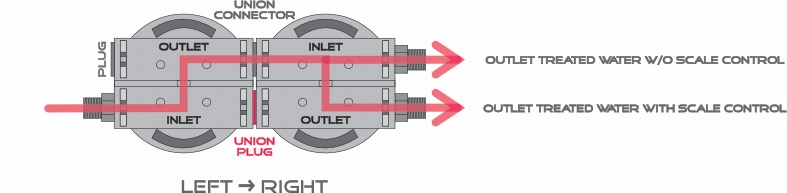

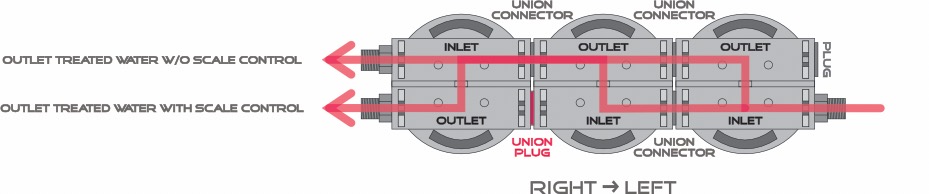

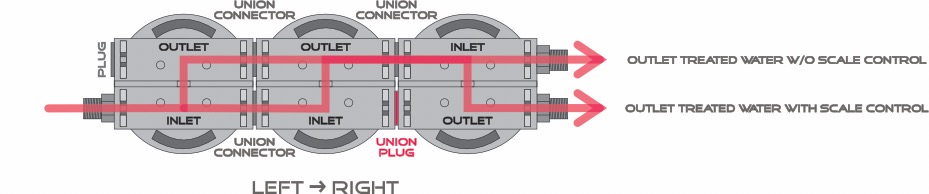

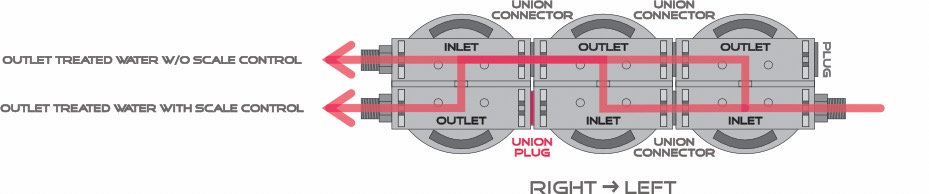

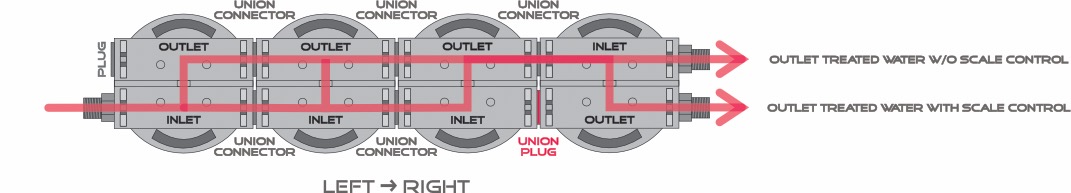

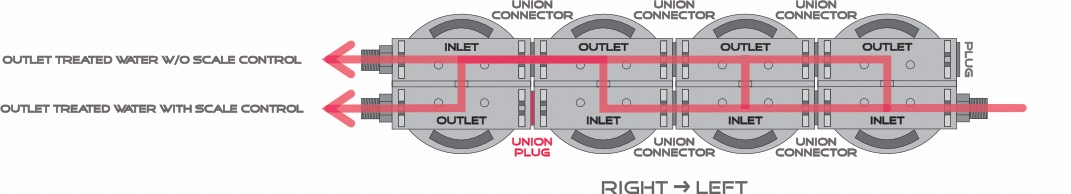

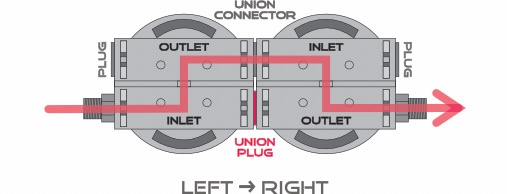

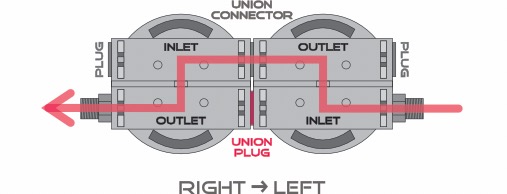

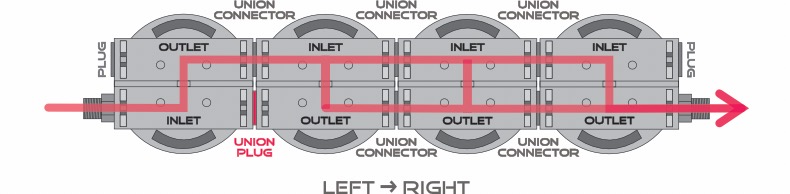

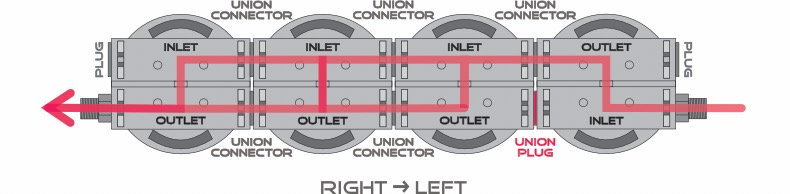

COMBO SYSTEMS

The Combo

filter systems provide sediment filtration, chlorine removal and mineral scale control. These systems provide two chlorine-free water outlets in one system. One with scale control and one without. The Combo System can be utilized for all water-fed equipment needs in one system. Ideal for whole store filtration. By request, Combo systems are available with TOF and TOC filters.

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal. (Chlorine Removal)

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 1.65 gpm.

Capacity: 10,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate: 3.3 gpm.

Capacity: 20,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate: 4.95 gpm.

Capacity: 30,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

Flow Rate: 2.0 gpm.

Capacity: 15,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate: 4.0 gpm.

Capacity: 30,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate: 6.0 gpm.

Capacity: 45,000 gal.

Applications: Whole Store Filtration

Download Spec Sheet:

Flow Rate:

-1.65

gpm

Capacity: 10,000 gal.

Applications: Drinking Water, Soda, Juice

Download Spec Sheet:

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.